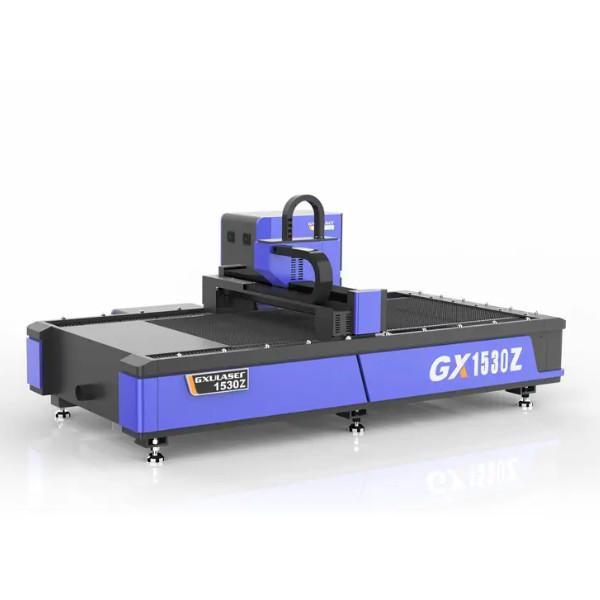

Imishini yokusika yensimbi ye-Metal Laser iguqula indlela amabhizinisi aqhutshwa ngayo embonini yokukhiqiza neyokukhiqiza. Ngobuchwepheshe obuthuthukisiwe nokunemba, le mishini isibe amathuluzi abalulekile amabhizinisi e-Metal Processing. Uma ibhizinisi lakho lifaka ukubonwa kwensimbi, kunezizathu eziningana zokuthi kungani ukutshala imali endaweni ye-laser yensimbi kuyisinqumo esihlakaniphile.

Ukunemba nokunemba

Enye yezizathu ezibalulekile zokuthi kungani ibhizinisi lakho lidinga umsiki wensimbi we-laser ukuthi le mishini inikezela ukunemba nokunemba okungenakuqhathaniswa. Izindlela zendabuko zokusika zensimbi zivame ukuphumela ekulimaleni nasekuxoxeni, okuholela ekuchithelweni kwezindleko kanye nezindleko ezandisiwe. Ama-Metal Laser cutters, ngakolunye uhlangothi, asebenzisa ugongolo lwe-laser olugxile ukuze asike insimbi ngokunemba okwedlulele. Lokhu kuqinisekisa imiphumela engaguquki futhi kuqede isidingo sezinqubo ezengeziwe zokuqeda.

Uhla olubanzi lwezinto zokwakha

Imishini yokusika yensimbi ye-Laserziyaguquguquka futhi zingacubungula izinto ezahlukahlukene. Noma ngabe usebenza ngensimbi engenasici, i-aluminium, ithusi, noma ithusi, le mishini ingayiphatha. Lokhu kuguqulwa kuvumela ibhizinisi lakho ukuthi lithathe amaphrojekthi ahlukahlukene ngaphandle kwesidingo semishini eminingi noma ukuphuma okwengeziwe, ukonga isikhathi nemali.

Thuthukisa ukusebenza kahle

Enye inzuzo enkulu yemishini yokusika yensimbi ye-laser ukwanda okukhulu ukusebenza kahle. Le mishini ingasika insimbi ngejubane elihlaba umxhwele, kunciphisa isikhathi esidingekayo kwiphrojekthi ngayinye. Ngokwengeziwe, imishini yokusika ye-laser iyakwazi ukusika imiklamo eyinkimbinkimbi namaphethini acishe afinyeleleke ngezindlela zokusika zendabuko. Ukusebenza kahle okwandayo kuvumela ibhizinisi lakho ukuthi lithathe amaphrojekthi amaningi futhi lihlangabezane nemikhawulo eqinile ngaphandle kokuyekethisa ngekhwalithi.

Gcina izindleko

Ngenkathi ukutshalwa kwezimali kokuqala kumsiki wensimbi we-laser kungabonakala kukhulu, kungaholela emalini ebalulekile yokonga ngokuhamba kwesikhathi. Ngobuciko babo obuqondile bokusika, imishini ye-laser inciphisa imfucuza yezinto ezibonakalayo futhi inciphise isidingo somsebenzi wezandla. Lokhu kunciphisa izindleko zokukhiqiza, kukhulisa umkhiqizo, futhi ekugcineni kuphumela enzuzo ephakeme yebhizinisi lakho. Ngokwengeziwe, ngokuba nomsiki we-laser endlini, uqeda isidingo sokukhishwa okubiza kakhulu futhi okudla isikhathi.

Ukusebenza Okungasebenzi

Imishini yokusika yensimbi ye-Lasernikeza okungaphezu kwamandla okusika nje. Le mishini nayo ingenza imisebenzi efana nokuqopha, i-etching, nokumaka, ukuvumela ibhizinisi lakho ukuba lithuthukise ubuhle bemikhiqizo yakho. Noma ngabe udinga ukwenza ngezifiso into yensimbi noma engeza imininingwane eyinkimbinkimbi, umsiki we-laser angakwenza. Ukuguquguquka okuhlukahlukene kwale mishini kuvumela ibhizinisi lakho ukuthi landise iminikelo yalo futhi lihlangane nezidingo ezibanzi zamakhasimende.

Ekuphetheni

Ukutshala imali endaweni yensimbi ye-laser kuyisinqumo esihlakaniphile kunoma yiliphi ibhizinisi elibandakanyeke ekubumbeni kwensimbi. Ukunemba, ukunemba, ukuguquguquka kanye nezinzuzo zokulondolozwa kwezindleko kule mishini enikezwa zibenze zibe yithuluzi elibalulekile emakethe yanamuhla yokuncintisana. Ngokwengeza ukusebenza kahle, ukunwebeka amakhono, kanye nokunciphisa izindleko zokukhiqiza, imishini yokusika yensimbi ye-wesal ingasiza ibhizinisi lakho ukuthi lihlale ngaphambi komncintiswano futhi lifinyelele impumelelo yesikhathi eside.

Isikhathi Sokuthumela: Oct-25-2023