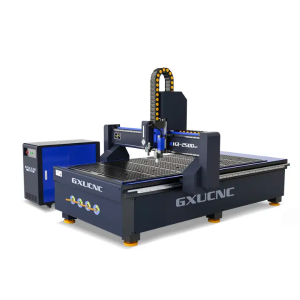

Imboni yokukhangisa yenze izithuthukisi ezinkulu ezinhlanganweni zokukhiqiza kanye nokuthuthukisa ubuciko. I-CNC Milling ubuchwepheshe obuguqule imboni. Ngokuqina kwabo okucacayo nokuguquguquka okuhlukahlukene okungekho emthethweni, imishini yokugaya i-CNC sekuyithuluzi elisemqoka lamabhizinisi ekukhangiseni, izibonakaliso kanye nasezinkameni zokumaketha. Kule bhulogi, sizohlola ukuthi ama-CNC gurters ashintsha kanjani imboni yokukhangisa futhi avukele indlela izikhangiso ezenziwa ngayo.

Ukunemba nokunemba:

Enye yezinzuzo eziphambili zemishini yokugaya ye-CNC embonini yokukhangisa yikhono lokusika izinto zokwakha ngokunemba. Noma ngabe ukusika igwebu ukuthola izimpawu ze-3D noma ukwakheka kwe-acrylic kokuboniswa, imishini yokugaya i-CNC iletha imiphumela engaguquki ngaso sonke isikhathi. Lokhu kunemba kwenza abakhangisi bakwazi ukudala ama-design ayinkimbinkimbi abenzima ngaphambili ukufeza ngesandla. Umphumela wokugcina uyisikhangiso esimangazayo esibambe ukunakwa futhi sishiya umbono ohlala njalo ezithangweni zakho ezihlosiwe.

Thuthukisa ukusebenza kahle nokukhiqiza:

Umkhakha wokukhangisa ukhuluma ngokuletha amaphrojekthi ngaphansi kwemikhawulo eqinile. Ama-routers we-CNC akhulisa kahle ukusebenza kahle kanye nokukhiqiza ama-ejensi wokukhangisa ngokuhlangabezana nalezinsuku zokugcina. Ngezinqubo zokunciphisa ezenzakalelayo, ama-CNC Mills angakhiqiza ngokushesha futhi ngokunembile ukukhiqiza amakhophi amaningi wokukhangisa, ukunciphisa isikhathi sokukhiqiza nezindleko. Ngokwengeziwe, le mishini ingagijima ngokuqhubekayo, incishise isikhathi sokuphumula. Abakhangisi manje bangathatha amaphrojekthi amaningi futhi bahlangane neklayenti lidinga ngempumelelo.

Amathuba okuqamba okungapheli:

Imishini yokuqopha ye-CNC iletha ukuklama okungapheliyo embonini yokukhangisa. Abakhangisi bangavula ubuhlakani babo futhi bavivinye ukwakheka okuhlukile, osayizi nezinto zokwakha. Ukusuka kumaphethini ayinkimbinkimbi wokubopha futhi ashukumisayo typefaces, imishini yokugaya i-CNC ingakwazi ukubhala, ukubhala bese usika izinto zokwakha kunoma yimuphi umklamo oyifunayo, enikeza abakhangisi Inkululeko yokudala iso lokubamba amehlo nokubukeka. Ngaphezu kwalokho, amandla okusika izinto ezahlukahlukene zokwakha kubandakanya izinkuni, ipulasitiki, igwebu nensimbi kunwebisa izinketho zemikhankaso yokukhangisa.

Isixazululo esisebenzayo esibizayo:

Ngokwesiko, imboni yokukhangisa ithembele kakhulu emisebenzini yezandla ukukhiqiza ukwakheka kokudala. Kodwa-ke, le ndlela ayisebenzi isikhathi kuphela kodwa futhi iyabiza. Imishini yokugaya i-CNC iguqule ukusebenza kwezindleko ngaphakathi kwemboni njengoba le mishini idinga ukungenelela komuntu okuncane, ngaleyo ndlela kunciphise izindleko zabasebenzi. Ngaphezu kwalokho, umshini wokugaya we-CNC futhi uphinde wandisa ukusetshenziswa kwezinto zokwenziwa, unciphise imfucuza futhi wehlise izindleko zokukhiqiza. Ama-ejensi wokukhangisa manje anganikeza amaklayenti ngokukhangisa okuphezulu okuthakazelisa kakhulu futhi okubiza kakhulu.

Ikhwalithi ethuthukisiwe nokuqina:

Ama-RNC Router enza izikhangiso ezikulololo isikhathi. Ngokusebenzisa okuqondile nokubumba, le mishini iqinisekisa ikhwalithi ephezulu kakhulu yemikhiqizo eqediwe. Noma ngabe kungokwesibonakaliso sangaphandle okuvezwe ezintweni noma isibonisi sokuphromotha esiqinile, umshini wokugaya we-CNC ungadala ukukhangisa okuzohlala. Ukuphela kwalezi zikhangiso kunomthelela omuhle kuhlobo lomkhangisi nobungcweti, ngaleyo ndlela kukhuthaza ukwethenjwa kwamakhasimende nokwethembeka.

Ekuphetheni:

Ngokungangabazeki ama-routers e-CNC ashintshe embonini yokukhangisa, evumela abakhangisi ukuthi baphoqe imingcele ngokuya ngemiklamo, ukusebenza kahle, kanye nokusebenza kahle. Ngokwamukela lobu buchwepheshe, amabhizinisi embonini yokukhangisa ayakwazi ukuletha izikhangiso ezinhle kakhulu futhi ezihlala isikhathi eside ngokunemba okungenakuqhathaniswa nobuciko. Njengoba imishini yokugaya ye-CNC iqhubeka nokuvela, abakhangisi nabathengi bangabheka phambili ekubuseni okugqekeza phansi ngokuzayo.

Isikhathi sePosi: Sep-06-2023